Qualified AM and AC Standards for Scalable Excellence

Standards in additive manufacturing facilitate faster production, lower costs, and improved product quality.

Standardized Qualified AM Program

The standardized Qualified AM Program is designed to enable growth and scalability in additive manufacturing (AM). It ensures success within the industrial AM space by preparing manufacturers to establish qualified processes that meet the approval requirements of regulated and demanding industries. This program enhances accountability and scalability of AM solutions.

Standards in additive manufacturing facilitate faster production, lower costs, and improved product quality. To achieve consistent quality, standardized protocols are essential. Adopting these standards ensures that parts are produced to the highest level of quality.

1 – 2 Weeks

Defining the Scope of the Qualification

The first step involves identifying and clarifying the specific requirements for your additive manufacturing process. Linking your needs to the best matching ISO/ASTM standards. We work with you to determine the exact scope, including material properties, system configurations, and part complexity, ensuring that your qualification pathway is tailored to meet your operational and regulatory needs.

1. month

Assessment of the Status Quo

We assess the current state of your systems and processes to evaluate their readiness for qualification. This includes a review of your existing quality management systems, production capabilities, and adherence to relevant industry standards, providing a clear picture of where improvements are needed to get you ready for the stage 1 audit.

1–3 month

Ramp-up Support

To help you achieve qualification efficiently, we offer hands-on guidance during the critical ramp-up phase. Our experts assist in the implementation of necessary changes, ensuring that your processes are optimized for compliance and performance from the start, setting you up for success in the upcoming audits.

4. month

Stage 1 Audit

During the Stage 1 audit, we perform a preliminary evaluation of your systems and processes to ensure they meet the foundational requirements of the qualification. This audit identifies any gaps or areas for improvement, allowing for corrective actions before the final certification audit. A detailed audit report containing a gap analysis is issued to you…

5. month

GAP Closing Support

Following the Stage 1 audit, we provide dedicated support to help you address any identified gaps. Our (expert) team works closely with you to implement the necessary changes and improvements, ensuring your systems are fully aligned with qualification standards and ready for final review.

6. month

Stage 2 Audit

The Stage 2 audit is a comprehensive evaluation of your entire production and quality management system. This audit verifies that all corrective actions have been successfully implemented, and that your processes fully comply with the required standards, moving you one step closer to certification.

7. month

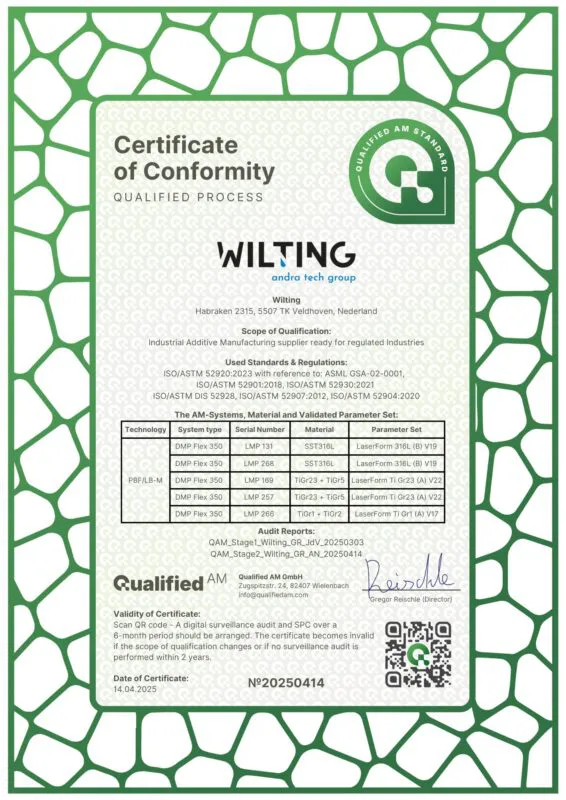

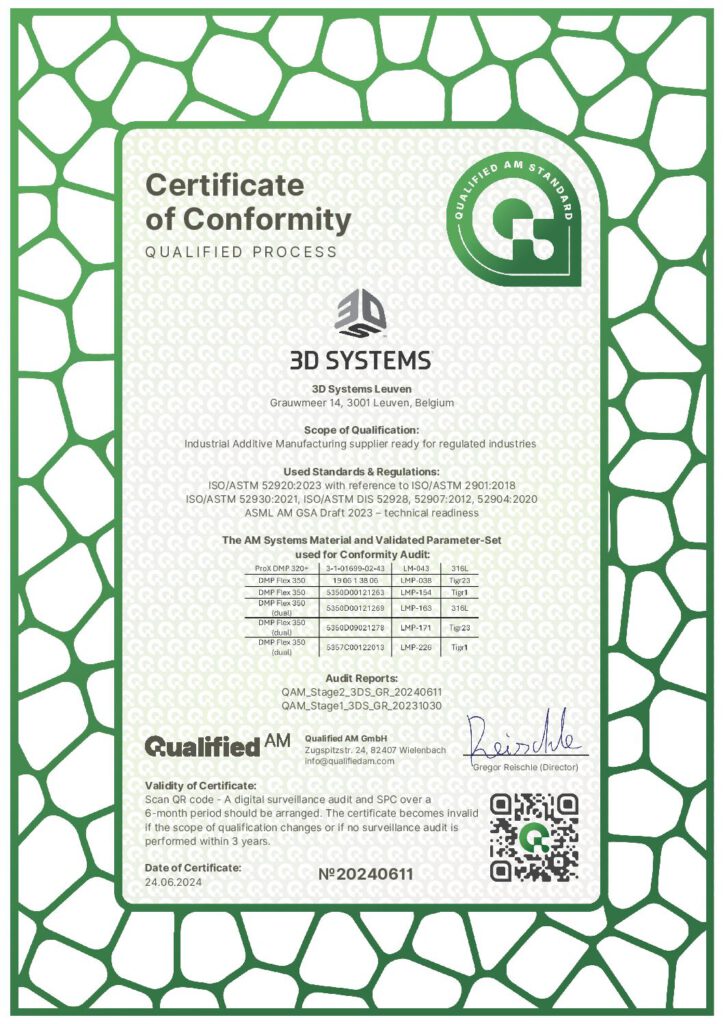

Certification

Upon successful completion of the Stage 2 audit, you will be awarded certification. This formal recognition confirms that your additive manufacturing processes meet the highest industry standards, enabling you to confidently enter regulated markets with a qualified and trusted production system.