Unlocks the possibility of regulatory acceptance for additive construction for the first time.

ISO/ASTM 52939:2023

Additive manufacturing for construction — Qualification principles — Structural and infrastructure elements

79

27

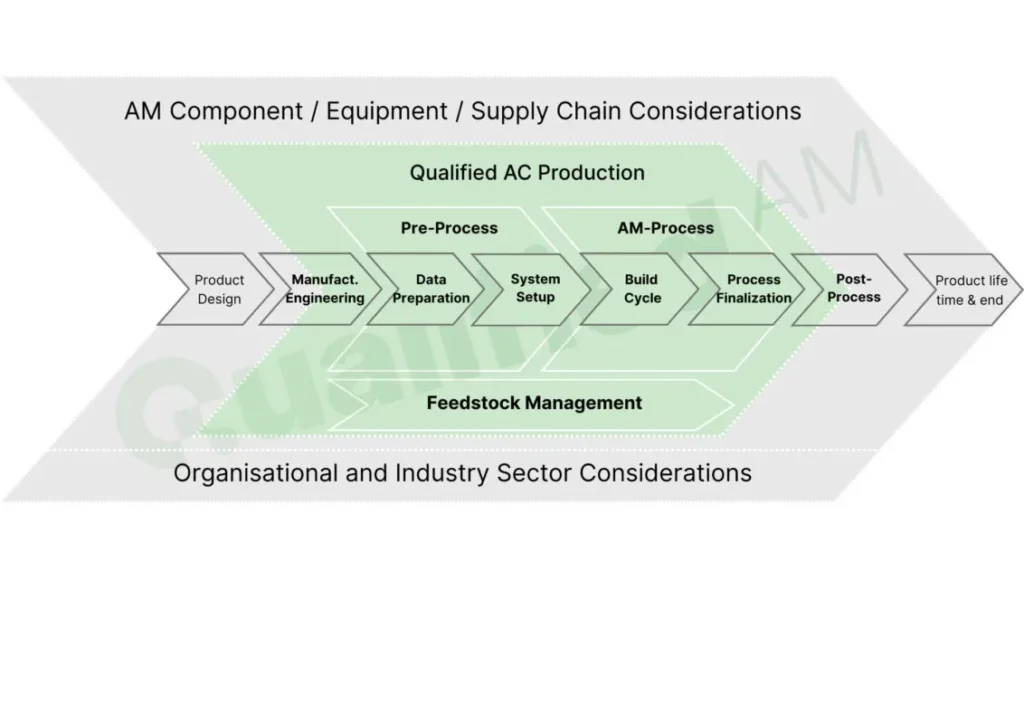

ISO/ASTM 52939 specifies qualification principles for additive manufacturing techniques applied to structural and infrastructure elements in construction. It defines essential quality assurance processes to ensure consistent and reliable fabrication of load-bearing and non-load-bearing components for residential and commercial building projects. This standard details necessary procedures including feasibility assessments, infrastructure setup, material management, additive construction (AC) process qualification, and comprehensive quality assurance measures. It is designed to be technology- and material-independent, serving as a guideline for organizations aiming to integrate additive manufacturing methods within established quality management systems and regulatory frameworks.

Value of Implementation

Implementing ISO/ASTM 52939 provides clear benefits by defining standardized principles for quality assurance in additive manufacturing for construction applications. This standard ensures consistent and reliable manufacturing of structural and infrastructure components by specifying key procedures, including feasibility assessments, infrastructure preparation, material management, and process qualification. Its technology- and material-independent guidelines support integration within existing quality management and regulatory systems, resulting in enhanced reliability and reduced project risks for both residential and commercial construction projects.

Correlation of the operational areas of AM

User Benefits

Supply Chain Manager

Quality/Production Engineer

Process/Operation Engineer

Supplier related with ISO/ASTM 52939:2023